Description

HAKKO Desoldering wire

■ Economical and easy-to-use desoldering wire

■ Handy for the removal of solder after dismounting surface-mounted components including BGAs

HAKKO WICK

■ Faster thermal transmission for superior performance at lower temperature and with lower wattage soldering irons.

■ Three different

· Regular type: Rosin flux treated copper braid

· Unflux type: Untreated copper braid

· No clean type: Low residue flux treated copper braid

Using ESD SAFE package

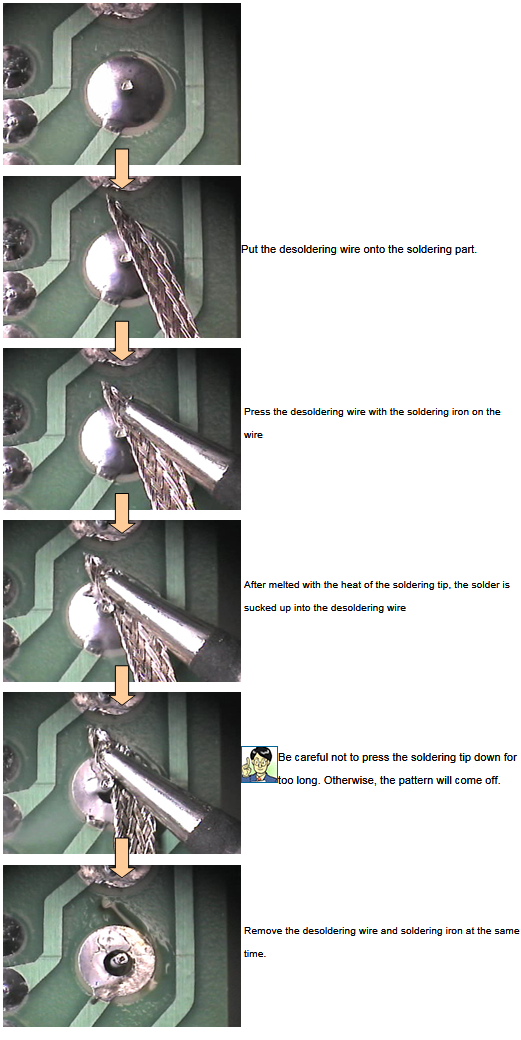

The ball grid array (BGA) has been removed from the surface of the printed circuit board (PCB).

Trick to remove solder well with the desoldering wire

Wrong use of the desoldering wire may tear patterns from a PCB or damage discrete components. In order to prevent these problems, make sure to take the preventive measure below:

Apply a bit of solder to the type of solder iron.

Apply a bit of solder to the tip of the desoldering wire. Cut the soldered tip of the wire at an angle of 45 degrees. Solder should remain attached.

Preliminary soldering improves heat conductance

| Item No. |

Part No. |

Name/Description |

| 224-0453 |

FR100-01 |

HAKKO WICK <REGULAR> 1.5MX0.9MM |

| 224-0462 |

FR100-02 (Discontinued) |

HAKKO WICK <REGULAR> 1.5MX1.4MM |

| 224-0471 |

FR100-03 |

HAKKO WICK <REGULAR> 1.5MX1.9MM |

| 224-0480 |

FR100-04 (Discontinued) |

HAKKO WICK <REGULAR> 1.5MX2.5MM |

| 224-0499 |

FR100-05 |

HAKKO WICK <REGULAR> 1.5MX3.3MM |

![[HAKKO] Desoldering wire](http://wowtoolz.com/cdn/shop/products/001_copy_f64c3c8f-439f-4687-a867-12976a29aada.png?crop=center&height=310&v=1570587796&width=430)

![[HAKKO] Desoldering wire](http://wowtoolz.com/cdn/shop/products/001_copy_f64c3c8f-439f-4687-a867-12976a29aada.png?height=310&v=1570587796)